Company

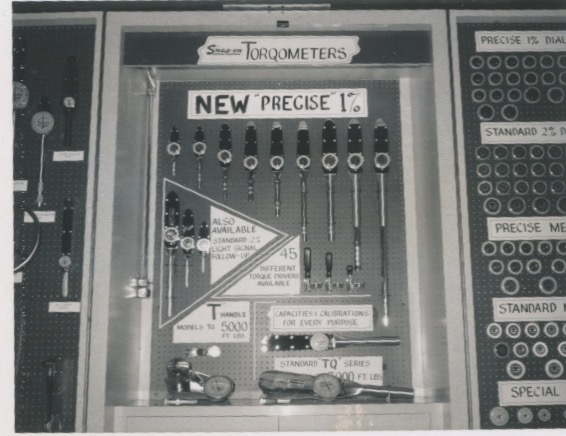

Precision Instruments was incorporated in 1938 to pursue the manufacture of the first torsion bar dial type wrenches. Central to the very first patent, awarded five years later, were the tenants of accuracy, reliability, and durability that have become synonymous with the Precision Instruments name. Over the next 24 years, the company would refine and elaborate on the torsion bar dial type wrench with advances that include increased accuracy and signaling options.

The same principles of torsion bar wrenches were extended to torque drivers in 1962, and the design was awarded a patent. Seven years later, Precision Instruments unveiled torsion bar standards for use in torque testers. These devices paved the way for adequate testing of torque wrenches in industries where a large number of torque wrenches are used. Virtually all modern torque testers trace their roots to this device.

In 1974 Precision Instruments successfully launched the split-beam click wrench market with the introduction of the C line. The wrenches solved many of the problems with traditional micrometer adjustable click wrenches and was awarded several patents.

By the early 1990s, Precision Instruments released the MD series of fully releasing drivers and received a patent for the design, detailing the mechanism for accurately applying torque with a fully-releasing driver type wrench.

Next Precision Instruments launched the M series micometer adjustable click style torque wrench and received a patent detailing the first mechanism for externally calibrating a micrometer-type torque wrench in both the clockwise and counterclockwise directions and with regard to spring rate. This patent was combined with a patent that allowed for the elimination of 95% of the friction in these wrenches.

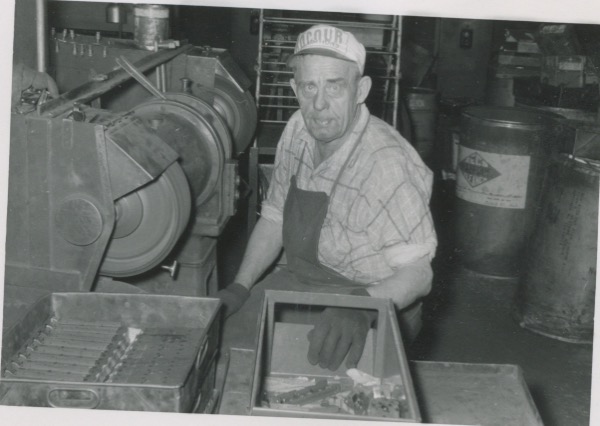

Precision Instruments occupies two buildings with a combined 50,000 square feet of floor space in Des Plaines, Illinois. Our plant’s machine shop performs press work, turning, milling, polishing, and plating. We also handle all assembly and calibrating on site.

To ensure that customers like you receive the highest quality instruments at the best value, we also utilize a strong chain of local businesses. These partnerships allow us to extend our capabilities and take advantage of many more manufacturing possibilities—all on your behalf.

At Precision Instruments, we are just as committed to you as we are to lean manufacturing. We believe that eliminating waste helps us deliver higher quality products and better customer service. Through quality control processes, inventory management, supply chain management and efficient product development, we strive to eliminate waste while maximizing value for customers like you.